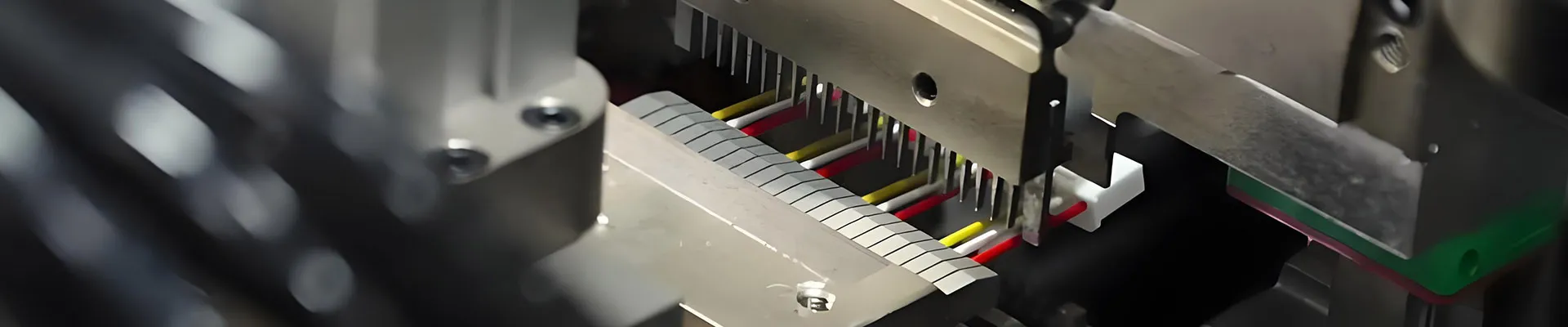

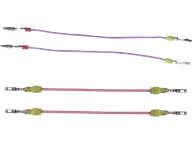

We offer automatic terminal crimping and sea insertion machines developed to achieve reliable wire harness production. This wire processing machines offers a comprehensive solution by combining terminal crimping with seal insertion, ensuring durability for wire assemblies exposed to moisture, heat, or other harsh conditions. It is particularly well-suited for automotive engine wiring, kitchen appliances, and communication base stations, providing consistent results for industries with high-quality standards.

Engineered to handle a variety of tasks, this wire terminating equipment performs wire cutting, stripping, double-sided crimping, and seal insertion efficiently. It supports diverse cable types such as 18AWG-28AWG electronic wires, including PVC, silicone, Teflon, and halogen-free wires.

Designed to efficiently process electric wires, high-temperature cables, halogen-free wires, and Teflon-insulated cables, this wire terminating machine automates essential steps such as cutting, stripping, crimping, and seal insertion.

This model of wire terminating machine integrates two-sided crimping and single-sided seal insertion, making it an efficient choice for processing 18AWG-28AWG wires.

Engineers with over 10 years of expertise in wire harness processing ensure innovative and reliable solutions.

Reliable equipment designed to optimize automation and efficiency in wire harness production.

Backed by more than 10 years of experience, we specialize in designing and manufacturing innovative wire processing equipment tailored to meet evolving industry needs.

Customizable features and modifications address unique production requirements across various industries.