Dongguan Ruihua Automation Equipment Company is dedicated to the research, development, manufacturing, and sales of various types wire processing equipment. Our product portfolio includes fully automatic housing insertion machines, tinning machines, multifunctional terminal crimping and tinning machines, ribbon cable processing machines, stripping and crimping machines, semi-automatic terminal crimping machines, wire stripping machines, and wire cutting machines.

Ruihua serves a wide range of industries, including automotive, railway, medical, home appliances, and renewable energy, offering tailored solutions to meet the specific requirements of each sector. Our wire and cable processing equipment is exported to regions such as Southeast Asia, Japan, Thailand, the Philippines, the United States, and Singapore, as well as over 20 cities across mainland China, including key industrial hubs like the Pearl River Delta and Yangtze River Delta.

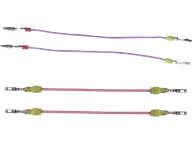

This crimping system is designed for two-sided terminal crimping of ribbon cables and individual wires without the need for additional components, only minor adjustments are required.

High-precision wire processing requires efficient equipment that can handle multiple tasks seamlessly. Designed for fine wires, our two-sided crimping machinery integrates automatic wire feeding, straightening, cutting, stripping, and terminal crimping into one cohesive process.

Handling up to 1,000 wires per hour, our multifunctional crimping solution supports processes such as cutting and crimping configurations such as one-to-two, one-to-three, and one-to-four wire setups.

Precision and flexibility are crucial for assembling wires of varying lengths in high-speed production environments. This model of wire terminating machine integrates cutting, stripping, terminal crimping, tinning, and housing insertion into one workflow.

High-volume cable assembly demands precision and efficiency, especially for wires requiring two-sided wire processing.

Our 2-sided crimping & 1-sided housing insertion solution supports two sides crimping and single-side housing insertion, making it ideal for producing complex wire harnesses.

Cable assembly processes demand precision and efficiency, especially when handling diverse wire configurations.

To address the need for efficient and precise cable assembly, this automatic wire terminating machine combines fully automated stripping and terminal crimping with the option for single stripping.

Engineered to handle a variety of tasks, this wire terminating equipment performs wire cutting, stripping, double-sided crimping, and seal insertion efficiently.