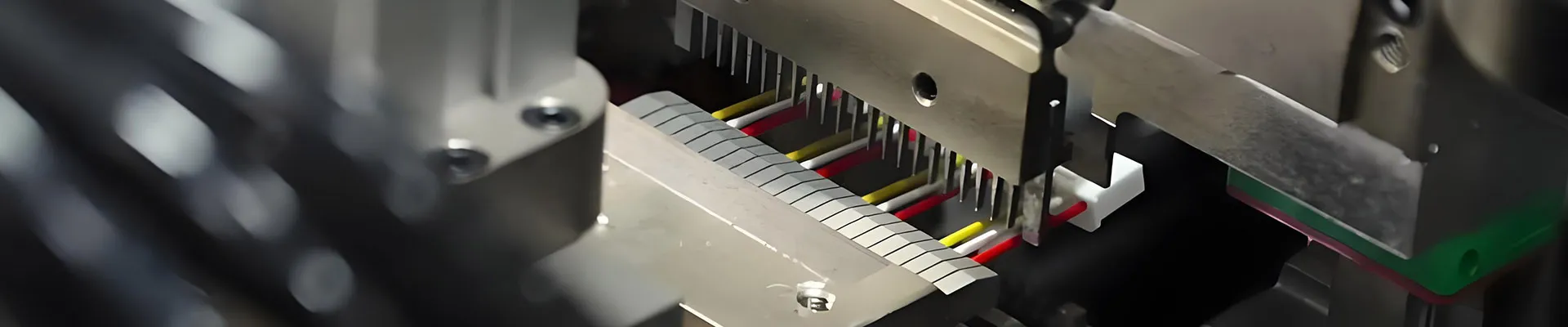

Ensuring secure and insulated cable connections is a important to achieve efficient wire harness production. Design to tackle this challenge, this type of wire terminating machine combines terminal crimping and sleeve insertion into one efficient process, handling tasks such wire cutting, stripping, and inserting protective insulation sleeves. It is suitable for applications such as signal transmission lines, sensor connection cables, audio wires, and automotive electrical systems.

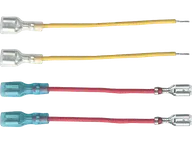

This model of wire terminating machine integrate two-sided terminal crimping with sleeve insertion, handling tasks such as crimping straight terminals (187/250) or inserting and positioning insulation sleeves.

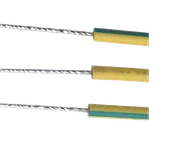

To produce high-quality cable assemblies, it’s important to use wire terminating equipment that can handle precise crimping and sleeve insertion. This wire terminating system supports operations such as single-end terminal crimping, sleeve insertion, twisting, and tinning, with a crimping capacity of 2,300 wires per hour.

Engineers with over 10 years of expertise in wire harness processing ensure innovative and reliable solutions.

Reliable equipment designed to optimize automation and efficiency in wire harness production.

Backed by more than 10 years of experience, we specialize in designing and manufacturing innovative wire processing equipment tailored to meet evolving industry needs.

Customizable features and modifications address unique production requirements across various industries.